Essays

Test

Vacuum-thermal chamber tests: performed in a space environment to verify the viability and functionality of devices, components, equipment, subsystems and space systems; thermal model validation tests.

Mechanical tests: modal characterization, sinusoidal and random vibration tests.

Orientation control tests on Helmholtz windings and anti-friction platform: tests of control laws, reproduction of the Earth’s magnetic field, tests on magnetic sensors and actuators.

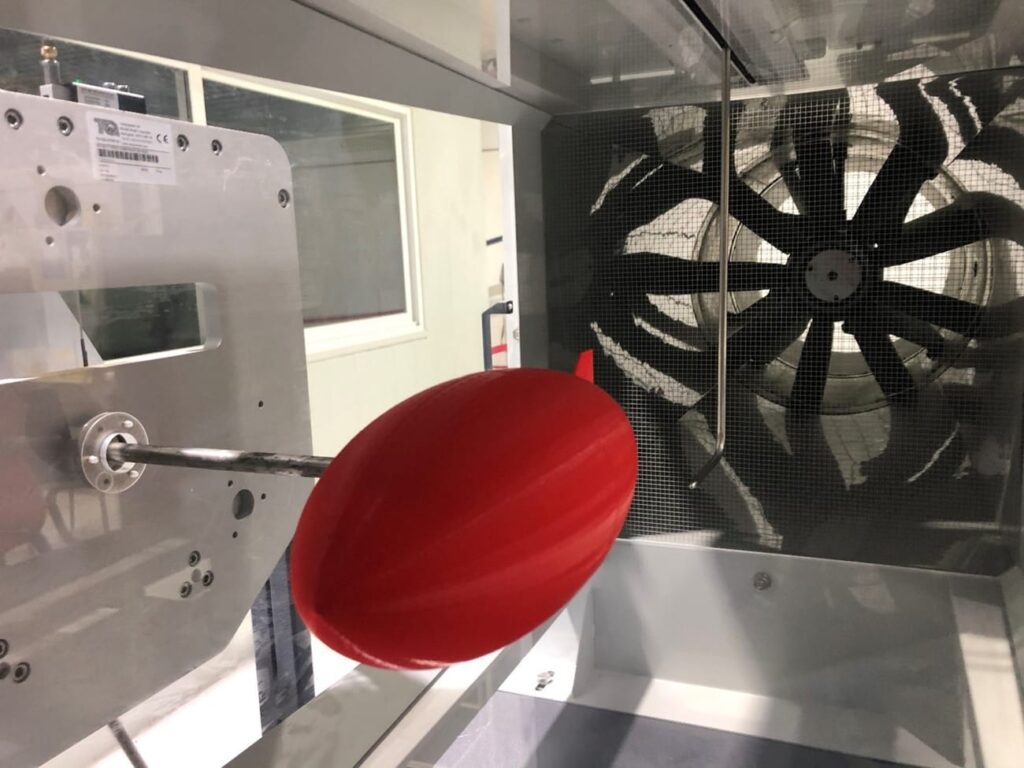

Aerodynamic tests in a low-speed wind tunnel. Rapid prototyping: design and manufacture of models in 3D printing or milling, planning and execution of tunnel testing campaigns, post-process of results and numerical simulation.

Electromagnetic compatibility tests (in collaboration with the Antennas, radar and communications group of the University of Vigo)

Equipment

Satellite tracking earth station, composed of two independent mechanical rotation systems. The main one is composed of 2 UHF antennas, 1 VHF antenna, and S-band and L-band antennas. Used for the operation of XaTcobeo, HumSat-D, Serpens and Lume. There is also a reserve station composed of 2 UHF antennas and 1 VHF antenna with an independent rotor.

2 cleanrooms class 1: 10000, equivalent to the ISO-7 standard (in Vigo and Ourense).

An anechoic chamber, capable of electromagnetic compatibility tests up to 3 GHz, and analysis of radiation patterns up to 50 GHz.

Cylindrical thermal vacuum chamber, with dimensions of 450 mm in diameter 500 mm in height; compatibility with a vacuum of 10E-2 mbar, temperature range of –150 ° C to +150 ° C, and heating/cooling rate of at least ±2ºC/min.

Mesa de vibraciones LDS – V830-335 (7kN). Posibilidad de ensayos en seno y random

Estación de ensayos magnéticos con bobinados Helmholtz y plataforma antirrozamiento

Túnel de viento de baja velocidad con sección de ensayos de 60 cm x 60 cm y velocidad máxima de 38 m/s

Impresoras 3D para la fabricación en más de 200 materiales de prototipos para ensayos: BQ Witbox 2, Ultimaker S3, Ultimaker S5.

Estación de mecanizado HIGH-Z S-1000 T (CNC step), en 3 ejes con resolución de hasta 0.005 mm y precisión de hasta 0.01 mm