Space thermal control

Space thermal control is the branch of space engineering whose objective is to ensure that all the elements of a space vehicle are within the temperature ranges necessary for the correct performance of the mission. There are two main reasons for the need for a thermal control subsystem in space missions

First equipment (both electronic and mechanical) usually operates efficiently and reliably in certain, sometimes reduced, temperature ranges. In general, a high percentage of the equipment comes from systems that have been designed to operate on land or are going to be built/mounted on it, so their operating temperatures tend to be at intervals around the temperatures usually found on our planet. In other cases, especially in large numbers of detectors, considerably lower temperatures are necessary to reduce noise in electrical measurements to acceptable levels. Exceeding these ranges can range from equipment malfunction to permanent damage.

Second most materials have non-zero coefficients of thermal expansion so that changes in temperature imply dimensional distortion or the appearance of thermo-elastic loads. Certain payloads require great dimensional stability for their correct operation, from measuring instruments such as telescopes to communication equipment with precise pointing, etc.

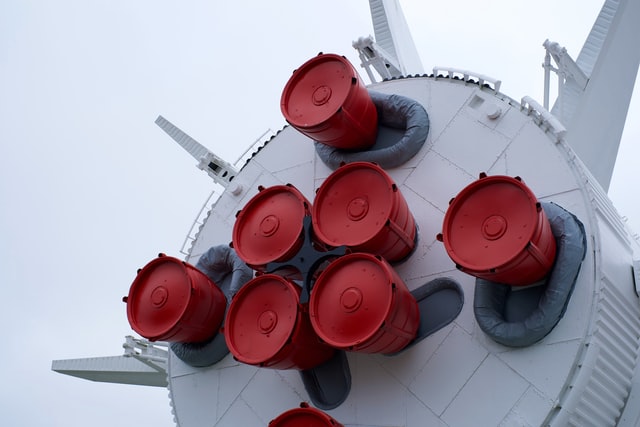

To space vehicles to be able to maintain the temperatures of their subsystems and equipment within the required values in any of these environments, it is necessary to design them using the appropriate means (technology, such as MLI space blankets or radiators to expel excess heat into space). That allows directing the heat flows as necessary, both inside the vehicle and between it and its surroundings.

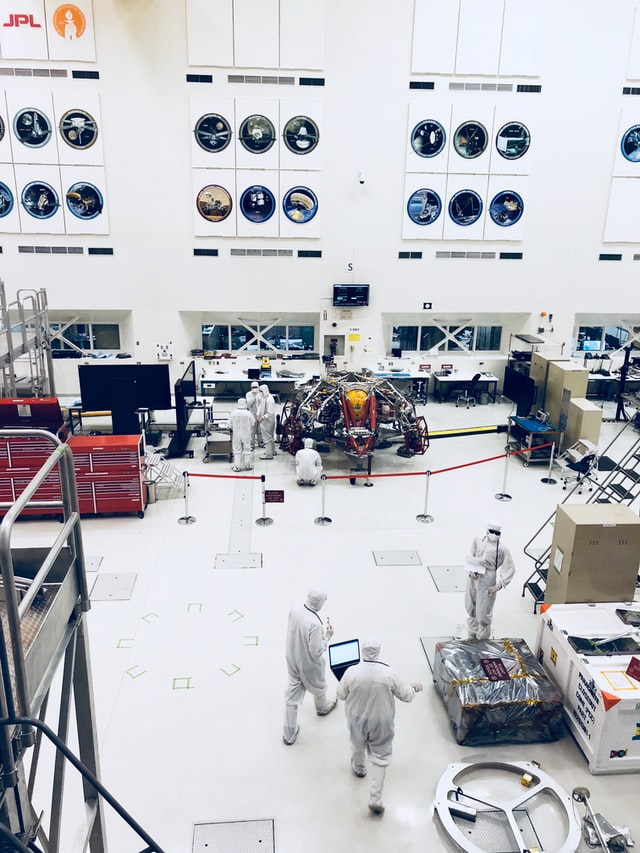

Responding to this series of external environments and internal requirements by employing the appropriate means to control heat fluxes in such a way as to meet the temperature requirements of a space mission is called thermal design. Thermal design evolves throughout all phases of each project, from the initial phases in which the degree of definition is small to the last phases in which the design is validated with the final testing campaign and closed.

Our current projects

ESA CDF RoboCrane – Lunar Caves (system engineering and thermal control)

HYPSO 1&2 (apoyo)